Laser cleaning is a modern-day simple approach to cleaning chrome steel. It uses excessive laser mild to dispose of rust, dust, paint, and other unwanted debris from surfaces. The high-quality component is that laser cleaning does not damage the stainless steel. Its most straightforward objectives are to dirt and leave the metallic accessible and vibrant.

We also discuss picking out a suitable laser cleansing device. Learn more.

What Is Laser Cleaning?

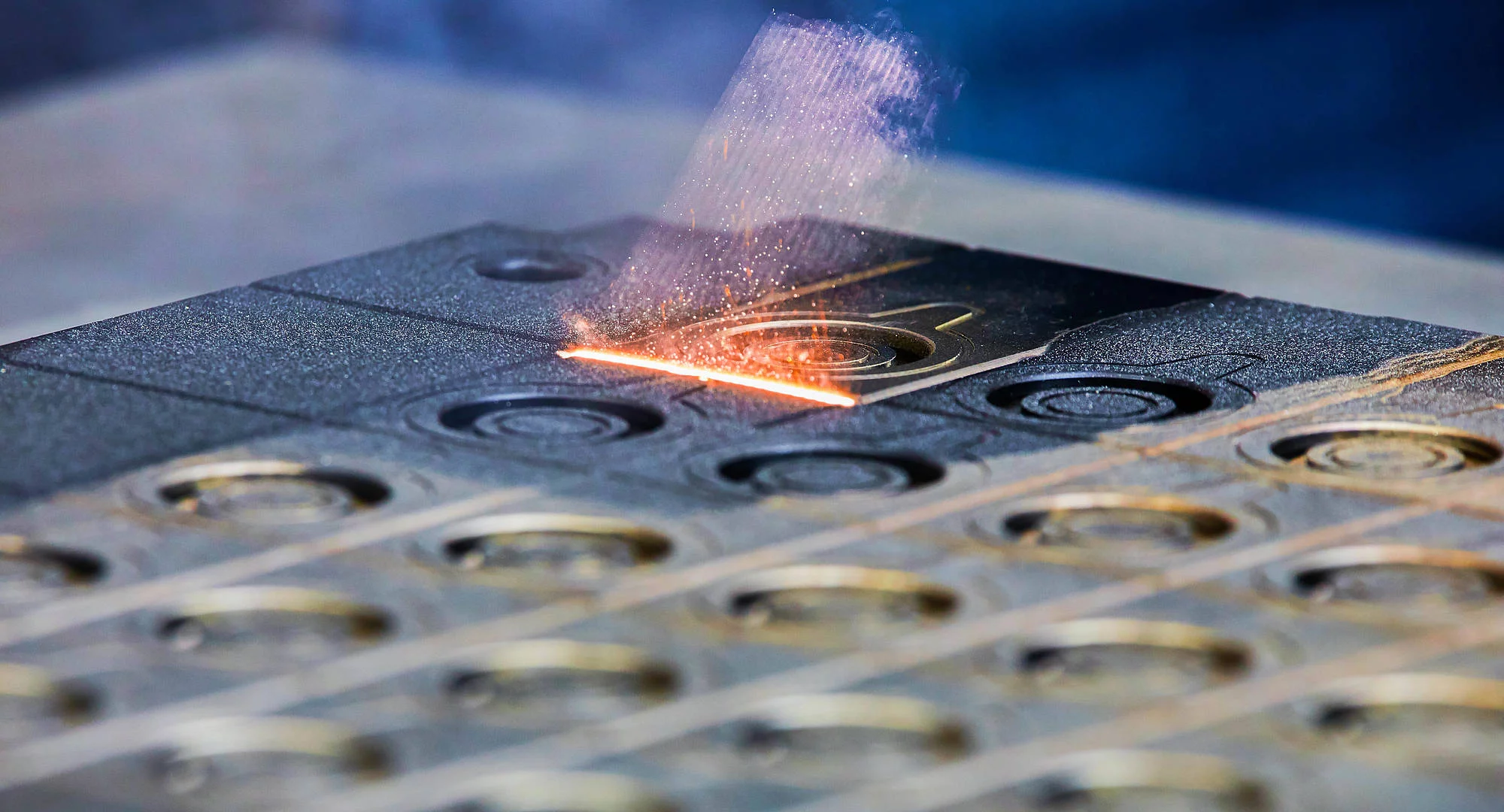

Laser cleaning: Directing a laser beam to ease a surface. The laser heats dust, rust, or paint on the floor, causing it to burn or crack. This cleans the stainless steel.

Laser cleaning could be very particular. It removes the floor layer of dirt or rust without being detrimental to the underlying metal.

How Does Laser Cleaning Work on Stainless Steel?

Laser light source:

The laser beam targets the stainless-steel floor wherein there’s dirt, rust, or paint.

Heating of the tubes:

The laser heats surface dirt or rust. This freezes or resuspends the dirt.

Removal of water:

Once the dust is clean, it may be blown or sucked via a vacuum cleaner to clean the eyes.

The laser can best target regions of particles, leaving the rest of the stainless steel untouched. This makes it a secure and practical approach to preservation.

Benefits of Laser Cleaning for Stainless Steel

The iron did no damage:

Laser cleaning prevents corrosion or corrosion of stainless steel. It robotically removes dirt and rust, making the metal accessible and intact.

Not the surroundings:

Traditional cleansing techniques often use chemicals that may be harmful to the surroundings. Laser cleaning calls for no chemical compounds. It cleans best with mild, giving it a more green look.

Quick and efficient:

Laser cleaning is speedy. It can restore large gadgets in a quick amount of time, making it perfect for jobs in which time is essential.

It’s pretty accurate:

The laser can repair small regions without affecting the encircling part. It allows for cleaning elements with debris or sensitive substances.

Low upkeep:

Laser cleaners are smooth to hold. There is much less mess because no water or chemicals are used, and the device stays in terrific shape longer.

Where Is Laser Cleaning Used?

Many industries use laser cleaning in which chrome steel wishes to be wiped clean. Let’s check some of the highlights:

Construction:

In commercial settings, stainless steel parts can become dirty because of rust or grease. Laser cleaning eliminates these contaminants, ensuring that the components are smooth and ready to be used.

Automotive Services:

In automobiles, a few additives, including exhaust systems and engines, are made of stainless steel. Laser cleaning helps cast off rust and dust from these parts, preserving them properly.

Space Services:

Stainless metal is used in planes because it’s miles strong and corrosion-resistant. Laser cleaning allows getting rid of old paint and rust from plane elements to make sure they remain secure and durable.

Food Services:

Hygiene could be very critical within the meal enterprise. Stainless steel is utilized in kitchen home equipment because it is straightforward to smooth and does now not rust. Laser cleaning facilitates the casting of grease and metal debris from the device, ensuring a smooth and secure environment.

Maritime Services:

Stainless steel is generally used in ships and other marine device. Laser cleaning helps eliminate rust and salt from stainless-steel elements of ships, preserving them in top running order.

How to Choose the Right Laser Cleaning Machine for Stainless Steel

There are a few things to consider when choosing a laser cleansing machine.

Laser Power:

The power of the laser may be very crucial. High-powered lasers can lessen large areas or put off heavy blemishes. But for small, delicate projects, a low-strength laser can be the acceptable option.

Accessibility:

If you need to hold the cleaner around, it’s miles fine to have a transportable one. Portable laser cleaners are lightweight and clean to transport.

Systems used:

Look for a gadget that is simple to maintain. Being capable of altering the placement of the laser is crucial for cleaning extraordinary surfaces.

Safety Precautions:

Ensure the gadget has safety features, including protective shields or computerized shut-off capabilities. This protects the users from any threat.

Cost and Maintenance:

While laser cleansing might also appear pricey, it does now not save you money ultimately. You’ll not have to buy chemical compounds or other cosmetics. Choose a product that is straightforward to keep and gives precise customer support.

Conclusion

Laser cleaning is a robust and powerful method of cleansing stainless steel. It’s rapid, accurate, and doesn’t corrode metallic. It’s additionally green as it doesn’t use any chemicals.

Laser cleaning is used in lots of industries, which include production, cars, aviation, aerospace, meals, and marine. It allows preserves stainless steel components to smooth and rust loose.

When choosing a laser cleansing device, don’t forget elements such as laser electricity, portability, managed structures, and safety functions. With the proper gadget, you can ensure that your stainless steel home equipment continues to be excellent.

Laser cleaning is an innovative, modern-day technique for stainless-steel care. This saves time, reduces costs, and is ideal for the environment.

Keep an eye for more news & updates on Discover Tribune!