Printing bags has changed a lot through the years. It began when humans did everything by hand; now, most paintings are done by machines. This change has made bottle printing faster, easier, and better. Let’s look at how Auto Print Bottle Printing Equipment has evolved from simple manual techniques to advanced machines.

Early Manual Techniques

Originally, packaging was printed by hand. People implemented designs on luggage using brushes, stamps, and stencils.

This was a slow and careful process. Each bottle had to be made one at a time, making it hard to make many bottles quickly. Since people were working, every bottle could look a little different. Mistakes happened often, and making all the bottles look identical was hard.

Even though it was slow, hand printing allowed for unique designs; the person printing could be creative and make each bottle unique. But as more bottles were needed, a faster way was necessary.

The Rise of Screen Printing

The first significant improvement in bottle printing came with screen printing. This method used a mesh screen to put ink on the bottle. The screen worked like a stencil, letting ink through in some areas to create the design.

Screen printing was much faster than doing everything by hand. It also made it easier to make many bottles that looked the same, which was necessary for companies that needed to make a lot of bottles.

Screen printing also made it easy to use more than one color. Using different screens for each color could create colorful designs on bottles, helping companies make their products look more attractive.

Introduction of Pad Printing

Screen printing became great, but it didn’t work well on weird round folders. To solve this, pad printing was created.

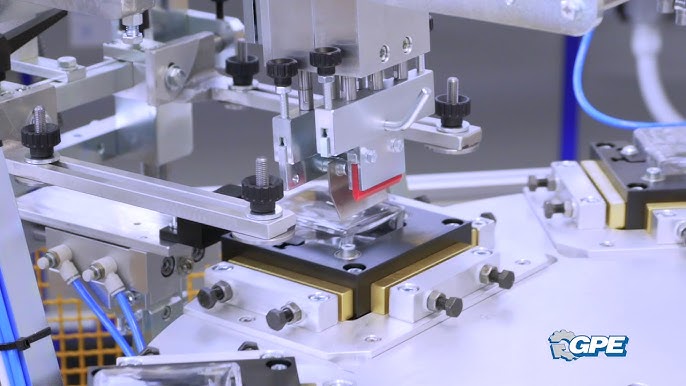

Pad printing uses a soft pad to move ink from a printing plate to the bottle. The pad can bend to fit the shape of the bottle, making it easier to print on rounded surfaces. This has made pad printing perfect for luggage, which includes beverages, perfumes, and cosmetics.

Pad printing can also be used on many surfaces, including glass, plastic, and metal.

Because of this, it became famous for many kinds of bottles.

The Move to Digital Printing

As technology improved, digital printing started to take over. Digital printing uses computer-controlled printers to put ink directly on the bottle. This method was better than screen and pad printing in many ways.

First, digital printing allowed for more detailed designs. With digital printers, it was possible to print high-quality images, complex patterns, and even photos on bottles. This level of detail wasn’t possible with older methods.

Second, digital printing was faster and more flexible. Since the design was stored on a computer, it could be changed quickly without making new screens or plates. This made digital printing great for small batches or custom products.

Lastly, digital printing was better for the environment. It used less ink and produced less waste than traditional methods. This made it a more eco-friendly choice for companies.

High-Tech Automation

The latest change in bottle printing is the move to fully automated systems. These systems use digital printing along with advanced robots and artificial intelligence.

Automated machine Auto Print Tech Co., Ltd can do everything, from loading the bottles to printing the design and packaging the finished products. These high-speed machines can print thousands of bottles per hour without human help.

Automation also ensures high quality. Automated systems can monitor the printing process and adjust to ensure every bottle is perfect. This reduces mistakes and ensures the finished bottles meet the highest standards.

Processors can also interoperate with other machines in the production plant. For instance, the completely automatic machine additionally consists of machines for filling, capping, and labeling bottles, as well as printing. This enables companies to be more efficient.

Customization and Personalization

One of the biggest trends in bottle printing today is customization. People want special and unique products, and high-tech printing equipment has made it easier for companies to offer custom bottles.

With digital and automated printing, companies can easily change designs to create personalized products. For example, a company could print bottles with a customer’s name or a special message. This kind of customization would have been impossible with older printing methods.

Customization isn’t limited to text. Advanced printing machines can create bottles with unique colors, patterns, and textures, giving companies many options to stand out in a busy market.

The Future of Bottle Printing

The evolution of bottle printing is still ongoing. As technology continues to grow, we can expect more exciting changes.

One area of growth could be 3D printing. While still new, 3D printing might one day allow companies to create fully custom bottles with complex shapes and designs. Another possibility is the use of intelligent technology in bottle printing. For example, bottles may be revealed with QR codes or other features that purchasers can experiment with on their phones to get new merchandise.

In conclusion

The evolution of bottle printing equipment has dramatically changed the industry. What commenced as a slow manual system has become a fast-paced and excessive-tech project. With advances in technology, the opportunities for bottle printing are infinite