Choosing the right hand welding extruder can make or break your plastic welding projects. Whether you’re a seasoned professional or new to the trade, selecting the right tool ensures not just efficiency but also the quality of your welds. With a variety of extruders on the market, each boasting unique features, it’s easy to feel overwhelmed.

In this ultimate guide, we’ll walk you through everything you need to know to choose the best hand welding extruder for your needs. From understanding the key features to evaluating your specific project requirements, this guide has you covered. Let’s dive in and make your decision process seamless.

1. Understand the Basics of Hand Welding Extruders

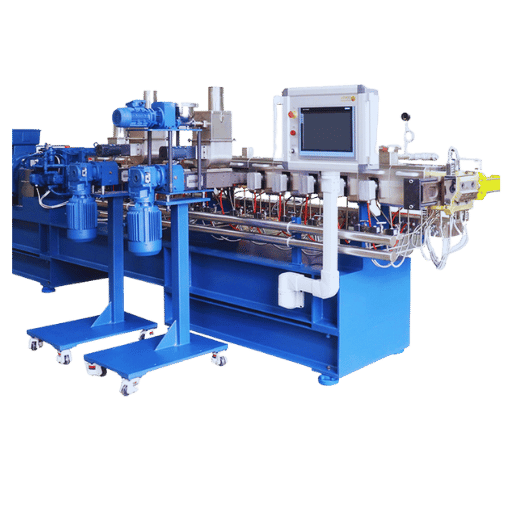

Hand welding extruders are portable tools designed for thermoplastic welding. They heat plastic rods or granules to create a strong, durable bond. Commonly used in industries like construction, automotive, and marine, they’re essential for precision and reliability in joining plastics.

Why they’re crucial:

- Provide precise control over weld quality.

- Ideal for both small repairs and large-scale projects.

2. Key Features to Look For in a Hand Welding Extruder

When selecting an extruder, keep these must-have features in mind:

- Adjustable Temperature Control: Ensures compatibility with different plastic materials.

- Ergonomic Design: Reduces operator fatigue during long sessions.

- Extrusion Rate: Determines the speed and efficiency of welding.

- Heating Elements: Look for durable and energy-efficient heating components.

- Built-In Safety Features: Overheat protection and cooling systems are essential for safe operation.

Pro Tip: Choose a model with a digital display for precise temperature and extrusion rate adjustments.

3. Consider Your Specific Project Needs

Your choice of extruder should align with your project requirements. Ask yourself:

- What materials will you be welding? Ensure the extruder supports the plastic types (e.g., PVC, HDPE).

- What is the project scale? For larger projects, opt for high-capacity extruders with faster extrusion rates.

- Do you need portability? Lightweight, cordless models are ideal for on-site projects.

4. Top Brands and Models to Explore

Here’s a look at some trusted brands in the hand welding extruder market:

- Leister: Known for precision and durability, their extruders are ideal for professional use.

- Rothenberger: Popular for user-friendly designs and high performance.

- Weldy: Offers affordable yet reliable models for budget-conscious welders.

Pro Tip: Check user reviews and ratings to gauge reliability and ease of use.

5. Maintenance and Longevity

To get the most out of your hand welding extruder, proper maintenance is key.

- Regular Cleaning: Prevents plastic residue buildup, which can affect performance.

- Replace Worn Parts: Periodically check and replace heating elements and nozzles.

- Store Properly: Keep the extruder in a dry, dust-free environment to prevent damage.

6. Cost vs. Value: What to Consider

While it’s tempting to go for the cheapest option, investing in a high-quality extruder saves money in the long run.

Factors to consider:

- Warranty and after-sales support.

- Energy efficiency for long-term cost savings.

- Compatibility with additional accessories, like specialized nozzles.

Conclusion

Choosing the right hand welding extruder doesn’t have to be a daunting task. By understanding your specific needs, prioritizing key features, and considering reputable brands, you’ll find a tool that enhances both the quality and efficiency of your work.

Remember, the right extruder is not just a tool—it’s an investment in precision and productivity. Take your time, do your research, and make an informed decision to ensure success in your welding projects.

Stay in touch to get more news & updates on Discover Tribune!