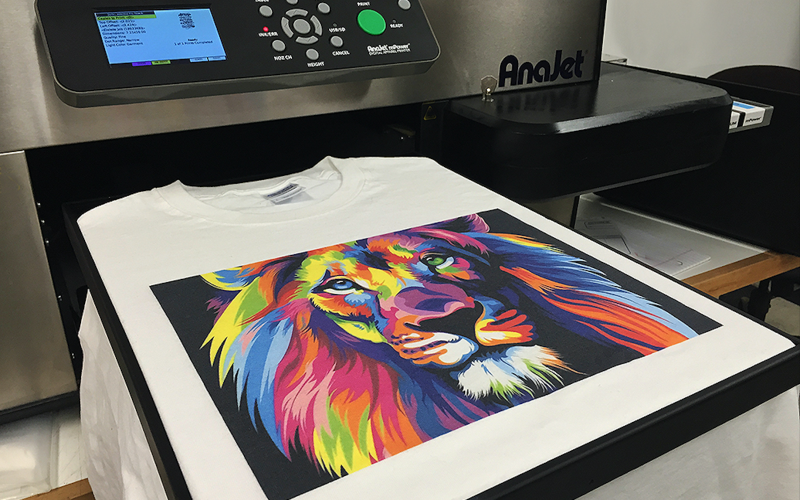

In the ever-evolving landscape of custom apparel design, direct-to-garment (DTG) printing has emerged as a revolutionary technology, offering unparalleled versatility, precision, and quality in creating customized t-shirts. Unlike traditional printing methods that involve screens, plates, or transfers, DTG printing allows for direct application of ink onto garments, resulting in vibrant colors, intricate details, and durable prints. In this comprehensive guide, we delve into the world of DTG t-shirt printing, exploring its benefits, techniques, and how it has revolutionized the landscape of custom apparel design.

Understanding Direct-to-Garment (DTG) Printing

Direct-to-garment t-shirts printing is a digital printing technology that allows designs to be printed directly onto garments using specialized inkjet printers. Unlike traditional printing methods that involve multiple steps and materials, DTG printing simplifies the process by eliminating the need for screens, plates, or transfers. This innovative technique offers several advantages over traditional methods, including:

Key Advantages of DTG Printing:

- Versatility: DTG printing can accommodate a wide range of designs, from simple graphics to complex illustrations and photographs, with precision and accuracy.

- Vibrant Colors: DTG printers utilize high-quality, water-based inks that produce vibrant colors and sharp details, resulting in prints that are visually striking and long-lasting.

- Durability: DTG prints are highly durable and resistant to fading, cracking, or peeling, even after repeated washing and wearing, ensuring longevity and quality.

- Customization: DTG printing allows for on-demand printing of custom designs, making it ideal for small-batch orders, personalized gifts, and one-of-a-kind creations.

- Environmentally Friendly: DTG printing uses water-based inks that are eco-friendly and free from harmful chemicals, making it a sustainable option for custom apparel production.

The Direct-to-Garment (DTG) Printing Process

The DTG printing process involves several steps, from design preparation to final curing, to ensure precise and professional results. While the exact workflow may vary depending on the equipment and software used, the fundamental steps remain consistent:

Step-by-Step Process:

- Design Preparation: Begin by preparing the desired design digitally using graphic design software. Ensure the design is formatted correctly and optimized for printing, with clear lines, colors, and resolution.

- Garment Preparation: Pre-treat the garment with a specialized pre-treatment solution to enhance ink absorption and ensure vibrant colors and sharp details in the final print.

- Printing Setup: Load the pre-treated garment onto the DTG printer platen and secure it in place. Load the digital design file into the printer software and adjust settings such as color, resolution, and print placement.

- Printing Process: Initiate the printing process, allowing the DTG printer to apply the design directly onto the garment using specialized inkjet printheads. The printer deposits layers of ink onto the fabric, building up the design with precise detail and color accuracy.

- Drying and Curing: Once printing is complete, dry the printed garment using a heat press or conveyor dryer to cure the ink and ensure durability. Proper curing is essential for achieving vibrant colors and wash-fastness in DTG prints.

- Quality Control: Inspect the printed garment for any imperfections or defects, such as misprints, color inconsistencies, or ink smudges. Make any necessary adjustments or touch-ups to ensure the final print meets quality standards.

- Packaging and Delivery: Once quality control checks are complete, fold or package the printed garments for delivery or distribution. Ensure proper packaging to protect prints from damage during transit.

Design Tips for Direct-to-Garment (DTG) Printing

To achieve professional results with DTG printing, consider the following design tips and techniques:

1. Optimize Design Resolution: Ensure the digital design file is formatted at the highest resolution possible to maintain clarity and sharpness in the final print. Use vector graphics or high-resolution images for best results.

2. Choose Suitable Garments: Select garments made from high-quality fabrics that are compatible with DTG printing, such as 100% cotton or cotton blends. Avoid fabrics with textured surfaces or coatings that may interfere with ink absorption.

3. Color Management: Calibrate color settings in the design software to ensure accurate color reproduction on the printed garment. Use color profiles and test prints to achieve consistent color accuracy across different fabric types.

4. Consider Print Placement: Pay attention to print placement on the garment, ensuring the design is centered, aligned, and proportional to the garment size. Consider factors such as neckline, sleeve placement, and overall visual balance.

5. Test Prints: Conduct test prints on sample garments before printing large batches to ensure print quality, color accuracy, and ink absorption. Make any necessary adjustments to design settings or garment pre-treatment based on test results.

Conclusion

Direct-to-garment (DTG) printing has revolutionized the landscape of custom apparel design, offering unmatched versatility, precision, and quality in creating personalized t-shirts and garments. By understanding the DTG printing process, exploring its benefits and techniques, and following best practices for design and production, you can unleash your creativity and produce stunning custom apparel that makes a lasting impression. Whether you’re designing custom t-shirts for a brand, event, or personal use, DTG printing opens up a world of possibilities for creating unique and memorable fashion statements.

Stay in touch to get more updates & new discovertribune.org!