Introduction

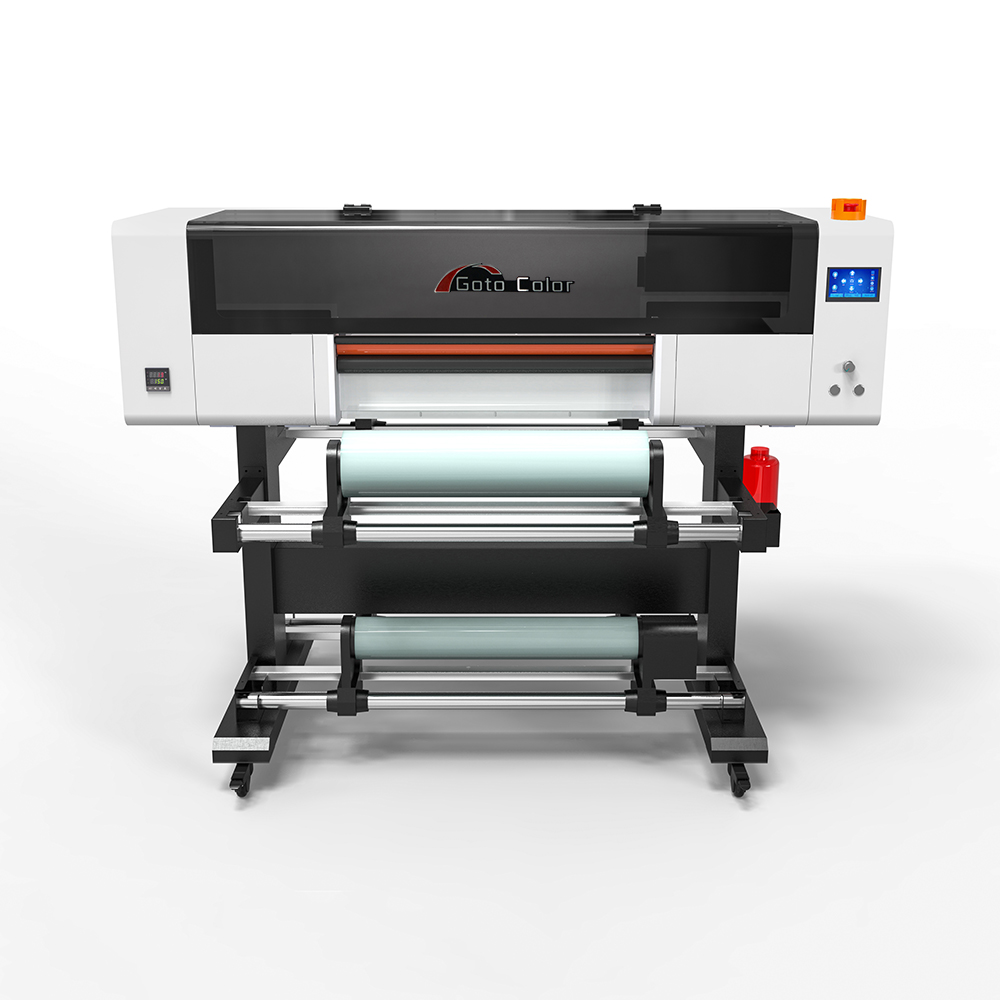

Improving labels with UV DTF printer technology means using its abilities. They make colors vibrant, show fine details, and add durability.

Enhance labels using DTF printer

Here’s a step-by-step guide on how to enhance your labels using UV DTF printer technology:

Design Preparation

Digital Artwork

Create or obtain high-resolution digital artwork for your labels. Ensure the artwork is suitable for UV printing, with sharp details and vibrant colors.

Software Compatibility

Use design software that supports UV DTF printing. For example, Adobe Illustrator or CorelDRAW. Set up your design file as the printer wants. Use the right color profiles and dimensions.

Selecting the Right Substrate

UV-Compatible Films

Choose UV-compatible films or transfer sheets suitable for DTF printing. These materials should withstand the heat and UV curing. They should not distort or degrade.

Surface Preparation

Ensure the substrate is clean, smooth, and free from dust or debris before printing. This helps achieve better adhesion and print quality.

Printing Process

Load the Printer

Load the UV DTF printer with the selected substrate or transfer sheet. Check that the printer is calibrated. Set it up as the manufacturer’s UV printing guidelines say.

Adjust Settings

Adjust print settings. These are for resolution, color, and ink. They optimize print quality and achieve the color you want.

Print Execution

Start the printing process. UV DTF printers apply UV-curable ink directly onto the film or transfer sheet. UV light instantly cures the ink. This ensures fast drying and adhesion to the substrate.

Post-Printing Enhancements

Finishing Options

Consider adding enhancements after printing. For example, you can laminate or coat with protective coatings (e.g., gloss, matte). This will improve durability, UV resistance, and looks.

Special Effects

Utilize the capabilities of UV DTF printing to add special effects such as embossing, textured finishes, or spot varnishes. These effects can create a unique look and feel for your labels, making them stand out.

Quality Control

Check out high quality DTF printers at dtflinko.com

Inspect Finished Prints

Check print quality. Make sure prints are accurate in color, clear, and stick to the paper.

Testing Durability

Test the labels for durability. See how well they withstand handling, abrasion, and relevant environmental conditions.

Application and Use

Application Method

Put the printed labels on products or packaging using suitable methods. Make sure they are aligned and stick well.

Storage and Handling

Store finished labels in a clean, controlled place. Do this to keep their quality and integrity. Keep them there until they are ready for use or distribution.

Compliance and Safety

Regulatory Requirements

Make sure that printed labels follow industry standards and regulations. This includes rules for product labeling. They cover safety, readability, and consumer info.

Applications of UV DTF Technology for Labels

Product Labels

Customized labels for branding, product identification, and compliance with regulatory requirements.

Food and Beverage Packaging

Labels for food containers, bottles, cans, and packaging materials that require moisture resistance and FDA compliance.

Health and Beauty Products

Labels for cosmetics, skincare products, and pharmaceuticals that demand high-quality printing and durability.

Industrial Labels

Durable labels for equipment, machinery, and industrial products that need to withstand harsh environments.

Expansion into New Applications

UV DTF printing will expand beyond traditional applications such as labels and apparel to include a broader range of substrates and products. This includes printing on ceramics, glass, metal, and other non-traditional materials for diverse industries like automotive, electronics, and home decor.

Sustainability Initiatives

There will be a continued focus on developing eco-friendly UV DTF printing solutions. This includes reducing energy consumption during printing, minimizing waste through efficient ink usage, and using recyclable or biodegradable materials where possible.

Enhanced Print Quality and Resolution

Future UV DTF printers will offer improved print resolution, finer details, and enhanced color gamut capabilities. This will meet the growing demand for high-definition graphics and photographic quality prints across various applications.

Regulatory Compliance and Safety

UV DTF printing systems will evolve to meet stringent regulatory requirements, especially in industries like food packaging and healthcare where safety and compliance are critical. This includes ensuring ink formulations meet FDA and other global regulatory standards.

Collaboration with Other Technologies

Integration with complementary technologies such as digital cutting systems (for die-cutting) and augmented reality (AR) for interactive packaging experiences will enhance the functionality and market appeal of UV DTF printed products.

Market Expansion and Adoption

As awareness and acceptance of UV DTF printing technology grow, its adoption will expand into new geographical markets and diverse industries. This will create opportunities for businesses to differentiate themselves through innovative and high-quality printed products.

Conclusion

Businesses can enhance their labels by following these steps. They should use the capabilities of UV DTF printer technology. This technology creates vibrant colors, intricate details, and durable finishes. This improves how things look. It also sets a brand apart, helps people see the product, and makes customers happy. This is important in competitive markets.

Stay in touch to get more updates & news on Discover Tribune!